Spot Welding

The fact is that most of us have heard of the term welding and welders but actually we lack the clear idea of what this entails. Most of the time we attribute this to a section of the technical work that encompasses lots of risk and strain. But what could be interesting is that this welding task could not be that risky job especially when you have the right skills and equipment.

A lot of people started as welding enthusiasts and even have later moved into their own business as it is a great guarantee of income. When you have some knowledge regarding this welding field, then it could be even easier taking it up as a job. The better part is that this is one job once you venture in you will not regret it. Let’s start by familiarizing ourselves with the term welding. This is a process that entails the combination of pressure and heat to melt materials and later having them joined with the filler materials. Though this fabrication process is risky, with the right knowledge then the task could be handled that smoothly.

Being a part of the industrial application, welding could be done using various energy sources such as electric beam, ultrasound, friction, laser, electric arc, and gas flames. Welders are mainly employed in most of the industrial sectors such as shipbuilders, fabricators, aero scope, and automobile. These people are usually highly exposed to fine particles, toxic gases. That is why most of the time they put on the protective equipment like the thick long-sleeved coveralls and the heavy-duty leather gloves. With the general knowledge of what welding entails, the article below we are going to pay more attention to spot welding.

Spot welding perfect for the exceptionally efficient joining technique

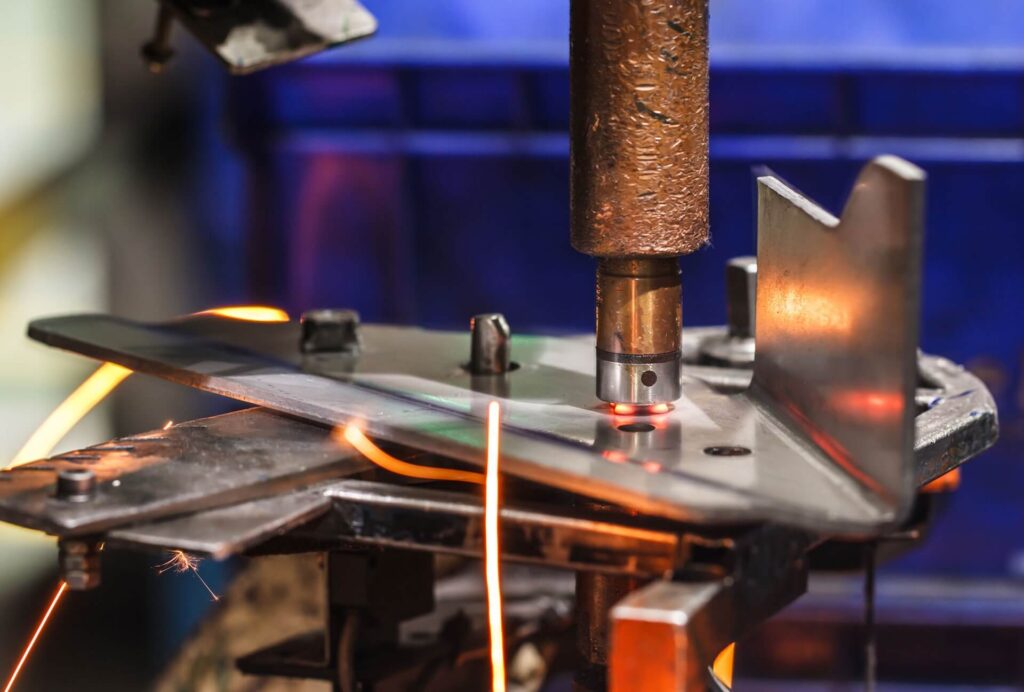

Spot welding is mainly termed as the exceptional efficient process that is best suited for the manufacturing of high volume, and for flexible alloys and most metals. Most of the companies that have the specialty in this sector mainly use the micro resistance spot welding link or choose connecting two metallic parts. Usually, the setting stone of this entire process is usually the application of the mechanical pressure and the electric current. The main feature of these spot welding is that there is always a lot of energy concentration to the spot in a short time.

By doing this, you will find a pit that the welding is done without causing a lot of heat to the entire sheet. Most of the companies that offer this specialized micro spot welder machine services usually provide the right assistance and guidance. This helps in making sure that you are selecting the right equipment for your application. However much most of the people think that spot welding is not that lucrative, the fact is that it is. There are several instances on the applications of micro joining and micro-welding in the industries. One of the areas where you can find this technique more used is in the automobile manufacturing industry.

You will find that parts of the automotive sensor, anti-lock brake system, battery pack connector, and the automotive ignition module among others use this technique. Another equipment that is a good example of the small-scale welding equipment application is that Orthodontists. There are some limitations and benefits of spot welding. Let’s start with the advantages: first, this type of welding effectively utilizes energy with very minimal amounts of pollution. Secondly, with this technique, there is mass production within the shortest cycle times. This is a process that is automated completely. More so, dissimilar metals and multiple sheets could be welded at an instance.

For the disadvantages, most of the metals can be welded easily though their application is usually limited to thin materials. additionally, most of the weld spots do not form continuous seams and thus the tensile strength could be that low. For the series or in-line soldering, it is better if you consider spot weld heads. And in the case of the automated applications, these could be used together with the air actuation system for the most reliable high-speed performances. With this, the rest re that consistent, precise depending on your requirements.

This is the best system that guarantees fast dynamic responses that begin the weld controls at the precise minute when the specific electro codes are applied to the workpieces. Most of the application of the spot weld heads entails miniature lamps, switch contacts, terminal connections, electrical connectors, battery pack assembly, and the small electromechanical parts.

It doesn’t matter your requirements or your applications, the durability and high performances of these welding techniques are unmatched. This equipment will provide you with unique solutions that could be even impossible or otherwise difficult for joining applications.

Resistance-Spot Welding – Basic Application Setup

Resistance welding always exists in several forms. We have the projection, seam, and spot. This is mainly used in the welding processes. Conversely, our main focus though is going to base on spot welding. When your concern is based on the quality of spot welding, then there are three principles that you need to understand. That is pressure, electrical current, and time. Therefore, in order for the operator to produce quality bonds between two metal pieces with a lot of consistency, then these three factors need to be balanced. The electro codes will conduct the current two pieces of metals that need to be fused since they are forged together.

The weld cycle needs building adequate amounts of heat through the electrical currents during that time the currents are applied in order to raise the small volumes of molten metals from the workpieces so as to bond. The molten metal then cools under the pressure of the electro codes until it sets high maximum strength that allows the metal holding the parts together. This is what is usually referred to as the hold time on the welder. And in case one of the parameters is changed without making the proper adjustments to the other, this could result in poor bonds.

For instance: when the current is increased without an adequate amount of pressure, this could result in the excessive weld splash. on the contrary, when there is a change in pressure without making the corresponding changes in current and time, this could result in poor welds as well.

The KVA ratings of welder resistance are greatly impacted by the various features of the machine’s set-up. When there is a small part that cannot fit in the short set of spot welder arm, this leads to the extension of the arm or changing it so as to make sure it can be able to accommodate the depth of the part.

Spot weld machines with long arms for deep entries of products can be bonded. This will have greater electrical impedances than the same KVA machines that have a short set of arms. In short, we can conclude that the electrical impedance will always reduce the resistance welder efficiency.

Electrical impedance is always the measure o the opposition electrical circuits present to the passage of currents when we have voltage applied. in terms of resistance welding, it is defining as the increased resistance due to the greater distances and obstructers that the current needs flowing through in order to get to its destination.

Contract Manufacturing Specialists of Michigan supplies is the best company when it comes to metal fabrication and steel laser cutting. The company specializes in the production and designing of the best store fixtures and point of purchase displays.

The company is not just known for its quality products but also for the best customer treatment. The company provides a diverse range of metal and steel products. We work hand in hand with our supplies customers in all relevant industries. Feel free to contact us or visit our website to get more information about our sport welding services.

Given the quality of staff and equipment that we have, you can be sure of getting the best rates from our brand. To benefit from our services, feel free to call us today. We have a team that is ready to give you the best services all the time.

Our core offerings and services at Contract Manufacturing Specialists of Michigan includes, but is not limited to, the following below:

We service multiple cities throughout the state of Michigan. We provide all the services listed above, and much more in every city throughout Michigan.

If you don’t see your city listed or a specific service listed, don’t worry. All you have to do is contact us by either giving us a call or filling out our online contact form. Then we’ll discover what are some of the top solutions for you, your business, and executing a solid solution.