CNC Turning

If you are not so synonymous with the metal fabrication business then you may never know what really goes on in these industries. The metal fabrication business is one wide industry that touches on almost all areas of metal production.

Any metal you see out there goes to the metal fabrication industry as raw metal then undergoes the fabrication process to get to what is always the final product. The fabrication process is what is the detailed part of this entire process. The process involves so many things but that only depends on the final product. If the final product is structural steel, for instance, the process will be carried out in a way that will lead to the manufacturing of structural steel. The same case applies to the other metals like sheet metal the end product among the others.

The metal fabrication process has been an evolving process over the years. As time goes by, new things come into this process with the aim of making it even more much streamlined and better. The industry has also grown with many other procedures coming in as well.

For instance, the process of automatic hardware insertion was not there in the past but most metal fabrication industries are now turning to this process. The progress is expected to go up even further in the coming days. The main reason why it is expected that things will happen this way is because of the innovation that is sweeping across the world currently. It is even predicted that the way industrial procedures will not be the case in the future. However, one thing that looks set to remain constant comes that time is the use of the machines in carrying out industrial procedures that come at that time.

The metal fabrication industry is one industry that is what is because of machines. Without them, it will not be possible to carry out any serious business. Whether it is cutting milling or even the other procedures, machines play a very big role in this industry. Even though there are projected changes to come in this industry in the days to come, none of those changes will do away with the use of machines in this industry. The machines will remain constant for many years to come in this industry, the only thing that will happen is that these machines will be made even much better.

Even today, there is no way you can succeed in the metal fabrication business if you don’t have the right machines. There are so many things that you will not be able to do in the right way. For instance, without the right machines, you will not be able to produce quality metallic products. Other than that, you will also not be able to carry out your business procedures fast enough to deliver your projects on time. These are some of the reasons that make machines so essential in the metal fabrication business.

You might be telling yourself oh well I need to get some machines now, that is not all. Not all types of machines can also help you to reach the success you need in this business, that is not the case at all. If you need the very best products in the market then you need to look for the best machines so as to achieve this. On the same topic of machines, there are only specific places where you can find the best machines for any metal fabrication business. For instance, if you are in the state of Michigan you can visit Contract Manufacturing Specialists of Michigan for the best metal fabrication machines.

These people have the very best of these machines that will help you to reach your metal fabrication business goals. From speed to accuracy to all the other essentials that are required for this process, the machines from these experts will help you to achieve these objectives.

Turning

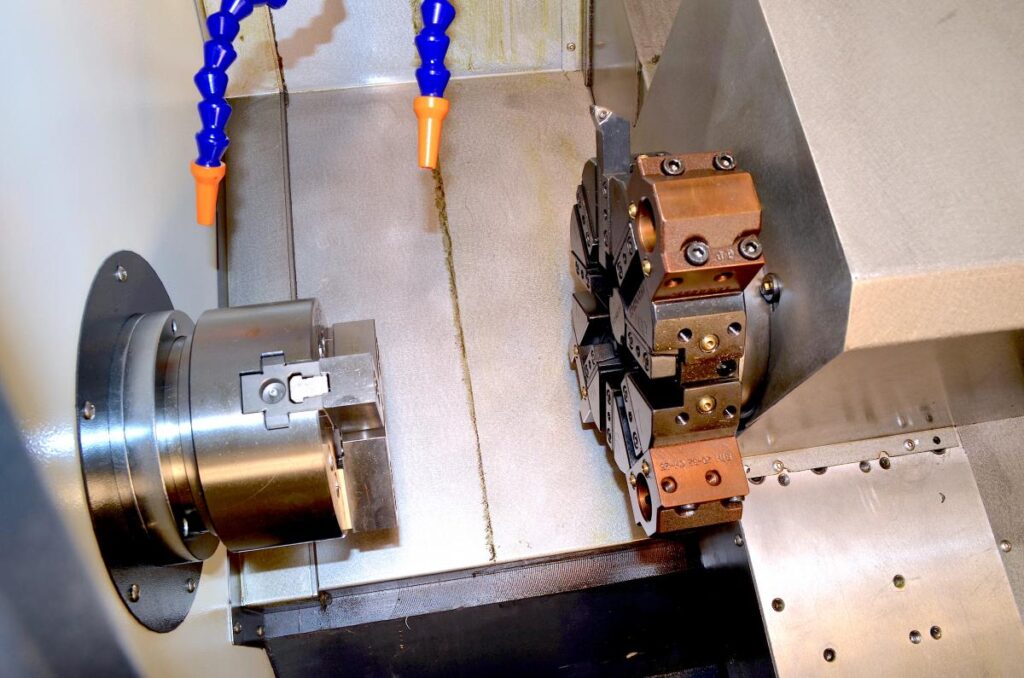

This is one of the main processes that goes on the metal fabrication business. It is a very complicated process that ought to be carried out with so much accuracy. So, what exactly is this process and how is it carried out. The process of turning is simply a detailed process of creating custom parts and other components using a lathe. There are so many ways that this process. For instance, a long time ago, this process was carried out manually with very little automation. The reason for this is because back then there was no technology that could allow or make it possible to use automation for this process.

As a result, this process was very slow and, in some cases, it came with some errors which compromised the quality of the end products so much. However, as technology has crept in, this process is becoming more and more automated. The automation of the process has brought with it some benefits like efficiency accuracy among many others. This has made it possible for the people in the metal fabrication business to carry out this process more efficiently and get the best more accurate results.

CNC Turning

The emergence of CNC machines has really transformed the metal fabrication sector making the industry more efficient and streamlined. Much of the success that is recorded in this sector is due to the impact brought about by these machines. The turning process has not been spared by these machines. CNC Turning today is a common process in areas where the turning process occurs. This can be termed as an upgrade compared to the way the same process was carried out a long time ago. There so many benefits that have been brought about by the same process. Many people who use CNC Turning find the process more beneficial in the following ways.

Reduced errors

The process of turning is one process that has to be carried out in the best way possible with the required accuracy. If there is anything being messed up then the results of this process will be nothing but a disappointment. Any messes will mean that the process will have to be repeated once again something that might come at the expense of the valuable company materials. To avoid such a thing from happening it is only right that this process is carried out in a careful way that will reduce any errors from occurring.

CNC machines are some of the machines that are known to come with a bigger deal of accuracy. When well-controlled, these machines deliver the best results compared to manual procedures. If you are carrying out the turning processes manually then you need to turn to CNC Turning. One of the benefits that you stand to get with the use of these machines in turning is the issue of reduced errors. These machines make very minimal errors compared to manual machines. This way, you can carry out your turning process for a long period of time without having to worry about some of these mistakes that might set you back.

A speedy turning process

Any metal fabrication process is one process where success is determined by so many things among them speed. You need to be fast enough in your production procedures and endeavors otherwise you will not make much. However, doing things manually cannot guarantee your speed as you may wish. You need to look for other ways of carrying out this process otherwise speed will be an issue to you. With the help of CNC machines, you will be able to carry out your turning process in the best way and most importantly with speed.

The accuracy that these machines bring means that you can carry out the process so well and within the shortest period of time possible. The best way you can use to carry out the turning process is by using CNC machines. These machines if well used will guarantee you many things among them speed as well as accuracy.

Given the quality of staff and equipment that we have, you can be sure of getting the best rates from our brand. To benefit from our services, feel free to call us today. We have a team that is ready to give you the best services all the time.

Our core offerings and services at Contract Manufacturing Specialists of Michigan includes, but is not limited to, the following below:

We service multiple cities throughout the state of Michigan. We provide all the services listed above, and much more in every city throughout Michigan.

If you don’t see your city listed or a specific service listed, don’t worry. All you have to do is contact us by either giving us a call or filling out our online contact form. Then we’ll discover what are some of the top solutions for you, your business, and executing a solid solution.